NTEGRATED,

INNOVATIVE AND SUSTAINABLE INDUSTRIAL PROCESS

Thanks to the verticalisation of processes, we can control the entire supply chain, from raw material to finished product. Moreover, the fact that we have 2 production plants makes FAG even more reliable in terms of risk assessment.

From the initial brief to delivery to the point of sale, FAG Artigrafiche's production process is characterised by meticulous attention to design, printing and assembly. Using specialised software, we aim to create tailor-made solutions, optimising yield and reducing waste.

Through 3D renderings, mockups and plotter-cut samples, assembly and transport solutions are tested practically. The prepress phase guarantees the quality of the printing plates, while offset printing ensures high definition and speed printing. The laminating and die-cutting process gives shape and strength to the material, while the final gluing, specialised in various ways, prepares the product for storage. Finally, the semi-automated warehouse with over 10,000 pallet places guarantees efficient logistics and shipping.

QUALITY SYSTEM

Operating within a quality system means applying its standards to every aspect of management-production activity with the aim of always achieving the best possible production, with optimisation of the individual operational phases.

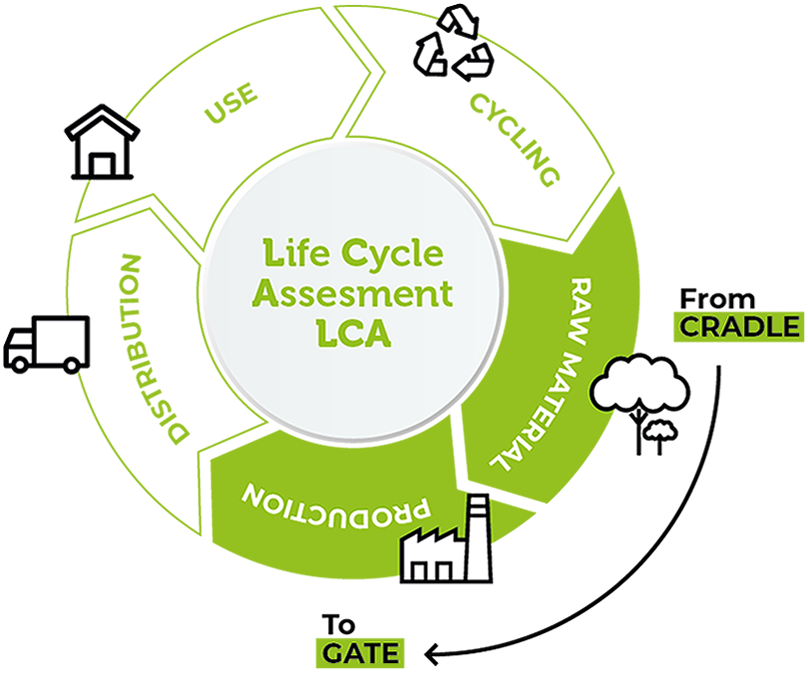

SUSTAINABLE

PRODUCTION

FAG Artigrafiche's environmental sustainability policies are an investment in the future of the community: every day we strive to meet present needs while safeguarding the planet for future generations. Our production methods are constantly evolving to save energy, reduce waste and achieve better quality products.